Pasteurization of products with low water activity

Destruction of micro-organisms in dry products with low water activities is a lot harder than in liquid media. Several reasons are postulated by scientists. The most relevant are:

- When only a small amount of water is available (low water activity), vibration of water molecules is limited. Therefore only a small amount of proteins are destroyed (denaturated) when heated.

- Micro-organisms in dry products have adapted themselves to stresses such as thermal, hydric and ionic, applied during the pasteurization treatment. This means they are more resistent and harder to destroy.

For the pasteurization of dry products this means that pasteurizing with dry air (or oil) requires a longer time rate than for wet products.

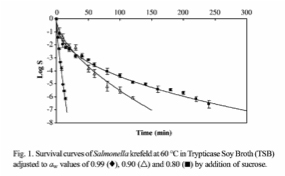

An example of the increased heat resistance of Salmonella in low water activity environments is shown in research from Chiewchan et al. from 2007:

Influence of water activity of tryptic soy broth on inactivation of S. krefeld at 60°C.

Log-time

How to pasteurize dry products

One of the more conventional approaches is to wet products with a direct application of steam, pasteurize, and then dry it. This approach, adequate for a number of products doesn’t work for processors who require a fresh, raw, original product.

This is why Log5 developed a system that lets you fully control the atmosphere, moisture and temperature of the pasteurizing environment. By regulating the atmosphere, the amount of water absorbed by the product is controlled, ensuring the quality of your end product and pasteurizing treatment are optimized.

Basics of Aw controlled pasteurization

The most important factors in keeping the quality of your treated product at its highest level:

Keeping the moisture content during processing at a defined level, prevents overheating and condensation of moisture on a cold surface. By preheating the product with a dryer air we are able to treat products which are sensitive to quality changes due to moisture uptake, and still achieve 5 Log kill rates.